Small business inventory tracker, the backbone of efficient inventory management, empowers small businesses to optimize their operations and maximize profitability. From tracking stock levels to forecasting demand, this guide delves into the world of inventory trackers, their benefits, and best practices, equipping you with the knowledge to make informed decisions and elevate your inventory management.

In this comprehensive exploration, we will uncover the advantages of utilizing an inventory tracker, delve into the key features to consider, and showcase success stories of businesses that have harnessed its power. Additionally, we will address common challenges and provide practical solutions to ensure seamless inventory management for your small business.

Inventory Tracking for Small Businesses

Inventory tracking is crucial for small businesses to efficiently manage their stock levels, reduce losses, and optimize their operations. It provides real-time visibility into the quantity and location of inventory, enabling businesses to make informed decisions about purchasing, production, and sales.

Various types of inventory trackers are available to suit the specific needs of small businesses. These include:

Manual Inventory Trackers

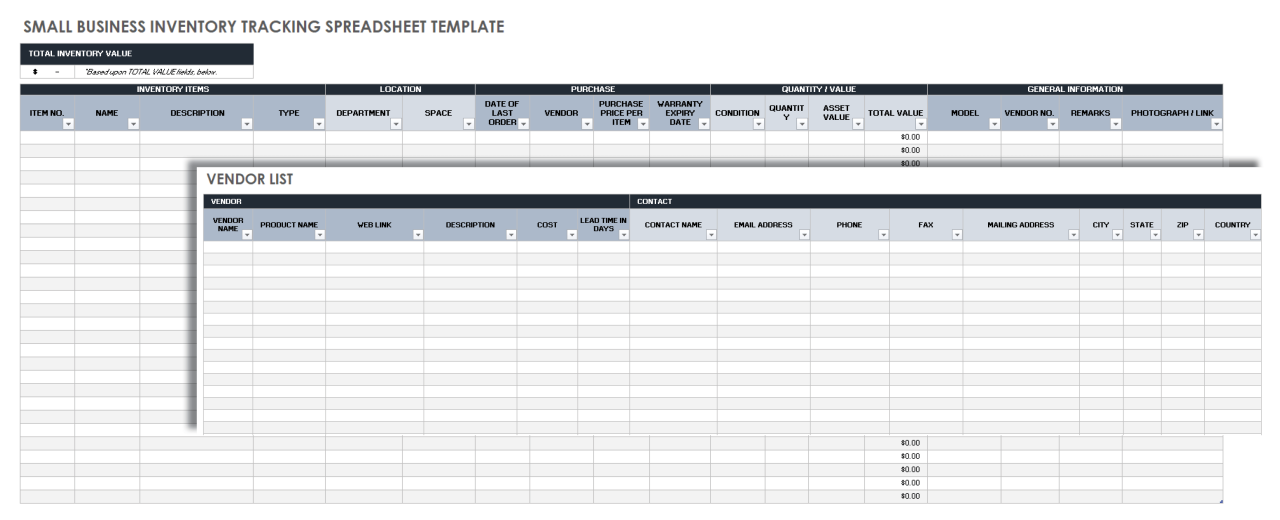

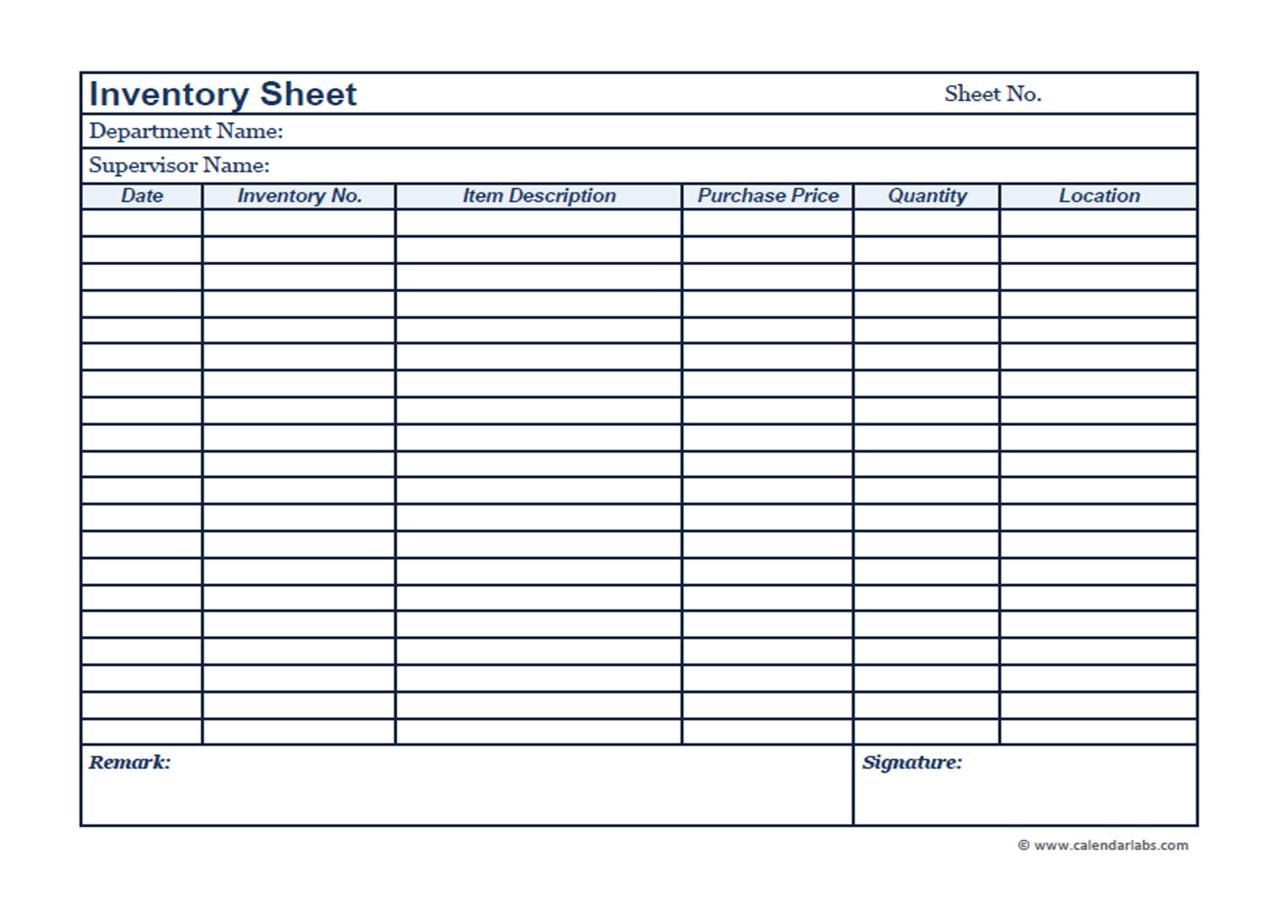

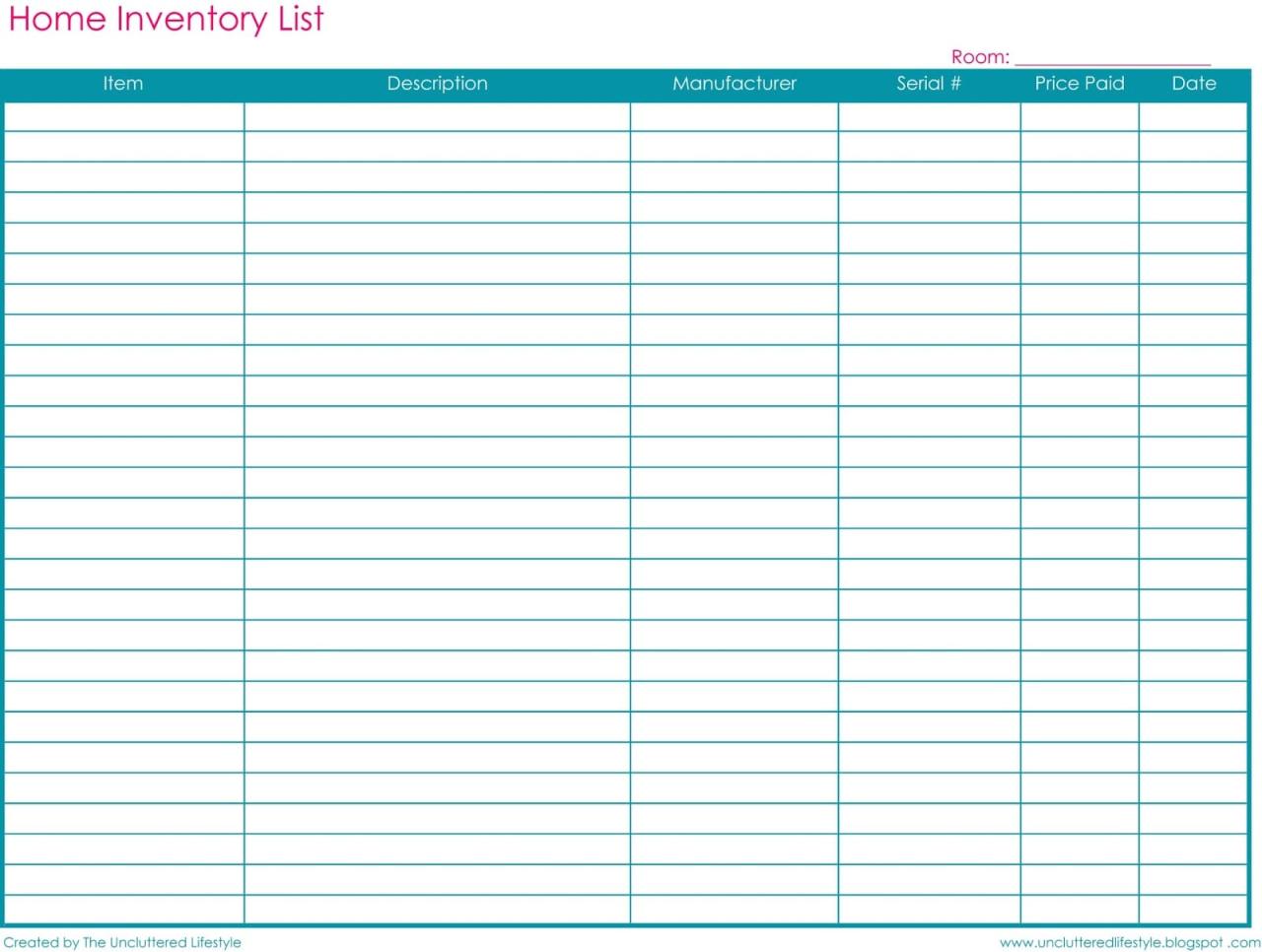

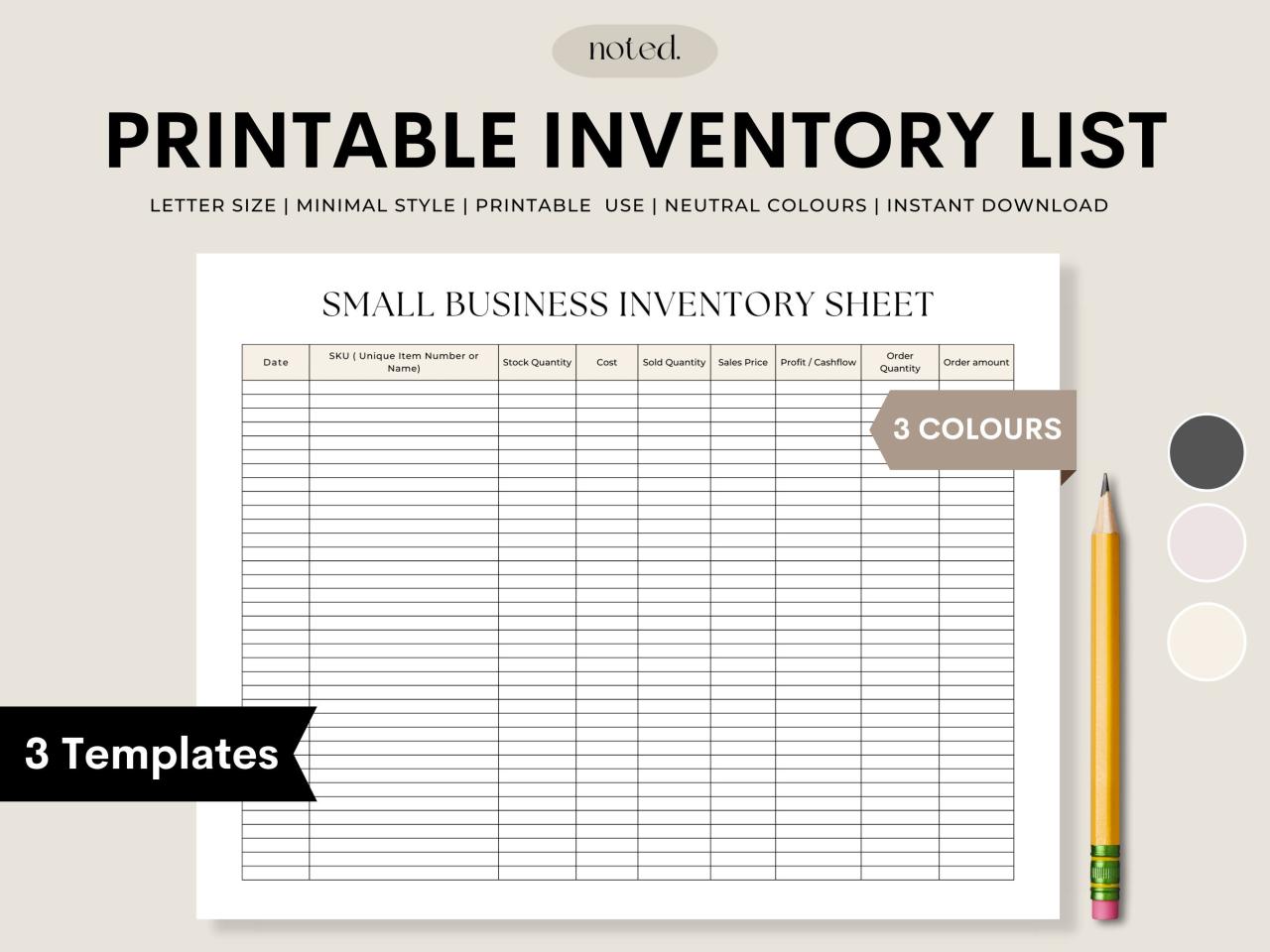

- Spreadsheets:Basic and cost-effective, allowing for manual data entry and calculations.

- Notebooks or Databases:Simple and portable, but prone to errors and limited in data analysis capabilities.

Automated Inventory Trackers

- Inventory Management Software:Comprehensive software that automates inventory tracking, provides real-time updates, and generates reports.

- Barcode Scanners and RFID Tags:Use technology to quickly and accurately track inventory items.

- Cloud-Based Inventory Systems:Accessible from anywhere with an internet connection, offering scalability and data security.

Best Practices for Small Business Inventory Management: Small Business Inventory Tracker

Maintaining optimal inventory levels is crucial for small businesses to balance customer demand, prevent stockouts, and minimize waste. Here are some best practices for effective inventory management:

1. Establish a clear inventory management system: Define processes for receiving, storing, tracking, and issuing inventory. This system should include clear roles and responsibilities for inventory management tasks.

2. Use inventory management software: Automated systems can streamline inventory tracking, reduce errors, and provide real-time data on stock levels. Consider cloud-based solutions for accessibility and scalability.

3. Implement regular inventory audits: Physical audits verify the accuracy of inventory records against actual stock levels. Conduct regular audits to identify discrepancies and ensure inventory accuracy.

4. Optimize inventory levels: Use inventory turnover ratios and other metrics to determine optimal stock levels. Consider factors such as demand patterns, lead times, and safety stock requirements.

5. Implement a perpetual inventory system: This system continuously updates inventory records as transactions occur, providing real-time visibility into stock levels. This can help prevent overstocking and stockouts.

Step-by-Step Guide to Implementing an Inventory Management System

1. Assess current inventory management practices: Identify areas for improvement and gather data on inventory levels, turnover rates, and lead times.

2. Select an inventory management software: Research and compare different software solutions based on features, cost, and scalability.

3. Implement the software and train staff: Install the software, configure settings, and train staff on its use and best practices.

4. Establish clear inventory management processes: Define roles, responsibilities, and procedures for receiving, storing, and issuing inventory.

5. Monitor inventory levels and make adjustments: Use inventory management software to track stock levels and make data-driven decisions on inventory replenishment and adjustments.

6. Conduct regular inventory audits: Verify the accuracy of inventory records by conducting physical audits and reconciling discrepancies.

Common Challenges and Solutions for Small Business Inventory Management

Managing inventory can be a complex task for small businesses. There are a number of common challenges that businesses face, including:

- Overstocking:Holding too much inventory can tie up cash and lead to spoilage or obsolescence.

- Understocking:Not having enough inventory can lead to lost sales and customer dissatisfaction.

- Inaccurate inventory records:This can lead to incorrect orders and poor decision-making.

- Inefficient inventory management processes:This can waste time and resources.

- Lack of visibility into inventory levels:This can make it difficult to make informed decisions about inventory management.

There are a number of solutions and strategies that businesses can use to overcome these challenges, including:

- Using inventory management software:This can help businesses to track inventory levels, automate ordering, and generate reports.

- Implementing a just-in-time inventory system:This can help businesses to reduce inventory levels and improve cash flow.

- Improving inventory forecasting:This can help businesses to avoid overstocking and understocking.

- Streamlining inventory management processes:This can help businesses to save time and resources.

- Gaining visibility into inventory levels:This can help businesses to make informed decisions about inventory management.

Future Trends in Small Business Inventory Management

The landscape of small business inventory management is constantly evolving, driven by technological advancements and changing consumer demands. Staying abreast of these trends is crucial for small businesses to optimize their inventory management practices and gain a competitive edge.

Emerging technologies such as artificial intelligence (AI), machine learning (ML), and the Internet of Things (IoT) are revolutionizing inventory management for small businesses. These technologies offer real-time visibility into inventory levels, automate tasks, and provide data-driven insights to improve decision-making.

Cloud-Based Inventory Management Systems

Cloud-based inventory management systems are gaining popularity among small businesses due to their affordability, scalability, and ease of use. These systems allow businesses to manage their inventory from anywhere with an internet connection, eliminating the need for on-premises servers and IT infrastructure.

Automated Inventory Replenishment

Automated inventory replenishment systems use algorithms to monitor inventory levels and automatically trigger purchase orders when stock falls below a predefined threshold. This eliminates the risk of stockouts and ensures that businesses always have the right amount of inventory on hand.

Data Analytics and Predictive Modeling

Data analytics and predictive modeling techniques are enabling small businesses to gain valuable insights into their inventory data. By analyzing historical sales patterns, businesses can forecast future demand and optimize their inventory levels accordingly.

Mobile Inventory Management, Small business inventory tracker

Mobile inventory management apps allow businesses to manage their inventory on the go. These apps provide real-time access to inventory data, enable barcode scanning for quick and accurate inventory counts, and facilitate order fulfillment and shipping.

Final Conclusion

![]()

As we conclude our journey into the realm of small business inventory trackers, it is evident that these tools are indispensable for businesses seeking to streamline their operations, reduce costs, and enhance customer satisfaction. By embracing the insights and strategies Artikeld in this guide, you can transform your inventory management practices, gain a competitive edge, and unlock the full potential of your small business.

FAQ Guide

What are the benefits of using a small business inventory tracker?

Small business inventory trackers offer numerous benefits, including improved stock accuracy, reduced manual errors, streamlined ordering processes, enhanced customer satisfaction, and optimized cash flow.

What are some examples of different types of inventory trackers available?

There are various types of inventory trackers available, including cloud-based systems, desktop software, mobile apps, and spreadsheet-based solutions. Each type offers unique features and capabilities tailored to specific business needs.

What are the key features to look for in a small business inventory tracker?

When selecting an inventory tracker, consider features such as stock tracking, purchase order management, barcode scanning, reporting capabilities, and integration with other business systems.

What are some best practices for managing inventory effectively for small businesses?

Best practices for effective inventory management include implementing a regular inventory audit schedule, optimizing stock levels based on demand, utilizing inventory tracking software, and training staff on proper inventory handling procedures.

What are some common challenges faced by small businesses in managing inventory?

Common challenges faced by small businesses in inventory management include stockouts, overstocking, inaccurate inventory records, and inefficient ordering processes. Implementing an inventory tracker can help overcome these challenges and improve overall inventory management.