Business inventorie – Buckle up, folks! Get ready to dive into the fascinating world of business inventory, where we’ll uncover the secrets to managing your stock like a seasoned pro. From inventory management systems to forecasting techniques, we’ve got you covered with a treasure trove of knowledge.

In this epic tale, we’ll explore the impact of inventory levels on your bottom line and customer satisfaction, leaving no stone unturned in our quest to optimize your supply chain. So, sit back, relax, and let the inventory adventure begin!

Inventory Management Systems

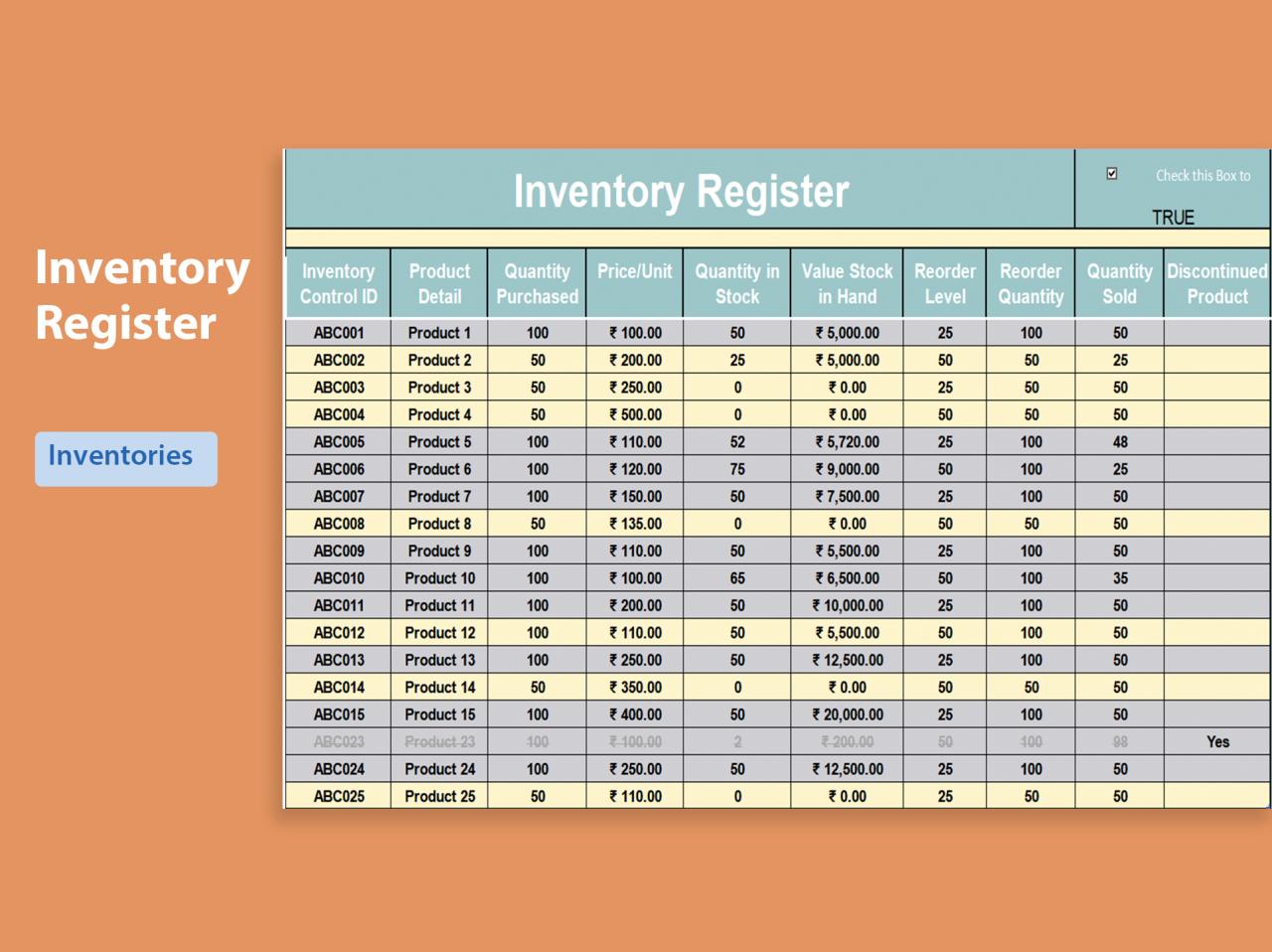

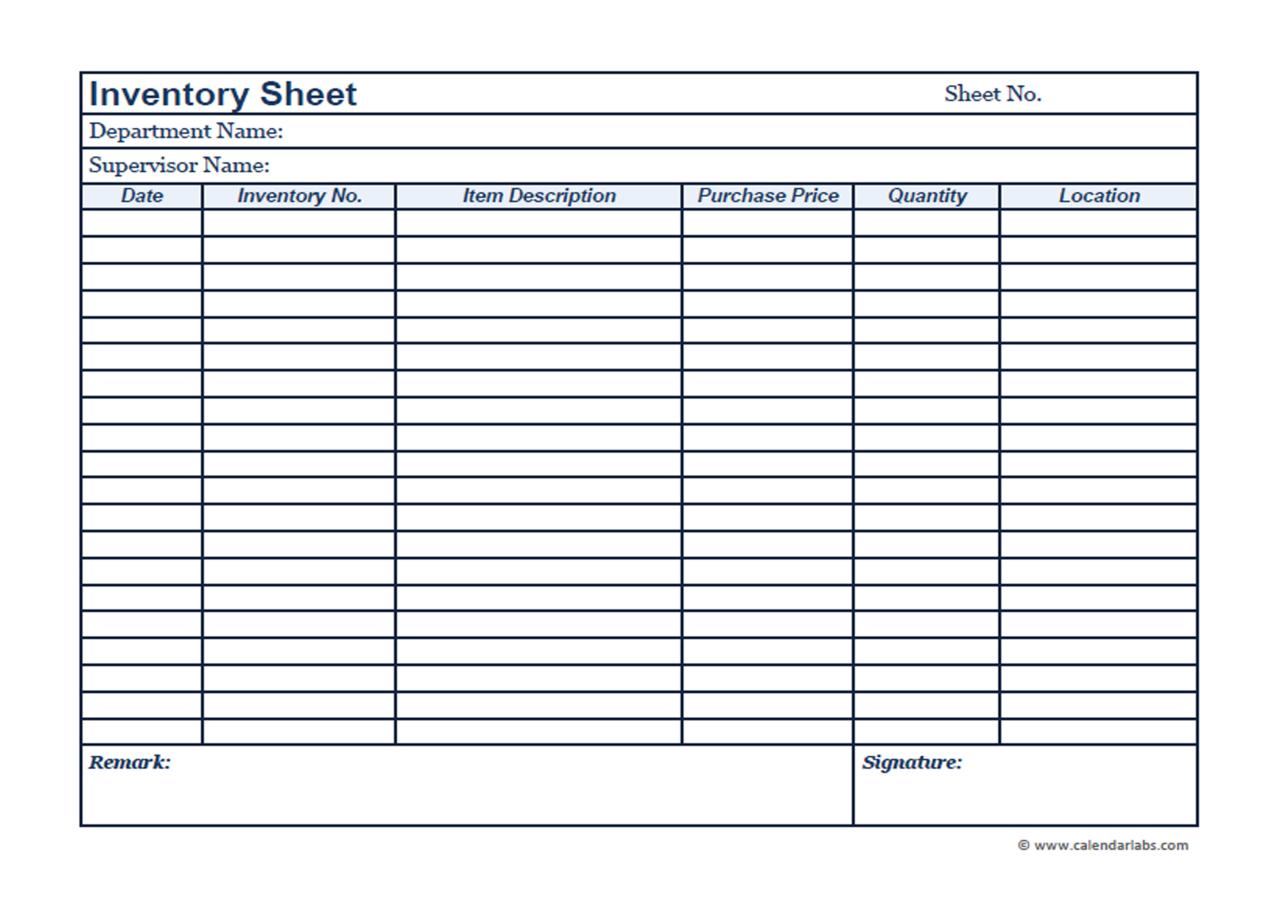

Inventory management systems are like the GPS for your business’s inventory. They help you track what you have, where it is, and how much it’s worth. This information is crucial for making informed decisions about purchasing, production, and sales.

Types of Inventory Management Systems

- Periodic Inventory Systems:These systems track inventory levels at specific intervals, such as monthly or quarterly. They’re less accurate than perpetual systems but are also less expensive to implement.

- Perpetual Inventory Systems:These systems track inventory levels in real-time. They’re more accurate than periodic systems but can be more expensive to implement.

- Hybrid Inventory Systems:These systems combine elements of both periodic and perpetual systems. They offer a balance between accuracy and cost.

Benefits of Implementing an Inventory Management System

- Improved Accuracy:Inventory management systems help you keep track of your inventory levels more accurately, reducing the risk of overstocking or understocking.

- Reduced Costs:By optimizing your inventory levels, you can reduce the amount of money you spend on purchasing and storage.

- Increased Efficiency:Inventory management systems can help you streamline your inventory processes, making them more efficient and less time-consuming.

- Improved Customer Service:By having a clear understanding of your inventory levels, you can better meet customer demand and reduce the risk of backorders.

Inventory Valuation Methods: Business Inventorie

Inventory valuation methods play a crucial role in determining a company’s financial health and performance. They directly impact the accuracy of financial statements, including the balance sheet and income statement. The choice of inventory valuation method can significantly affect profitability, cash flow, and tax liability.

Specific Inventory Valuation Methods, Business inventorie

There are several inventory valuation methods to choose from, each with its own advantages and disadvantages. The most common methods include:

- First-In, First-Out (FIFO):Assumes that the oldest inventory is sold first. This method can result in higher profits during periods of rising prices and lower profits during periods of falling prices.

- Last-In, First-Out (LIFO):Assumes that the most recent inventory is sold first. This method can result in lower profits during periods of rising prices and higher profits during periods of falling prices.

- Weighted Average Cost:Calculates the average cost of all inventory items, regardless of when they were purchased. This method results in a more stable cost of goods sold and gross profit margin over time.

- Specific Identification:Tracks the cost of each individual inventory item. This method is most accurate but also the most time-consuming and expensive to implement.

Impact on Financial Statements

The choice of inventory valuation method can have a significant impact on financial statements. For example, FIFO can result in higher reported profits during periods of rising prices because the cost of goods sold is based on older, lower-cost inventory.

Conversely, LIFO can result in lower reported profits during periods of rising prices because the cost of goods sold is based on more recent, higher-cost inventory.

Factors to Consider

When selecting an inventory valuation method, companies should consider several factors, including:

- Industry norms:Some industries have preferred inventory valuation methods.

- Tax implications:Different inventory valuation methods can affect tax liability.

- Profitability goals:Companies may choose a method that aligns with their desired profit targets.

- Cash flow needs:Certain methods can impact cash flow by affecting the timing of inventory expenses.

By carefully considering these factors, companies can select an inventory valuation method that best meets their specific needs and objectives.

Inventory Optimization Techniques

Are you tired of inventory woes? Do you want to make your inventory management a symphony of efficiency and cost-effectiveness? Look no further, my friend, for we’re diving into the magical world of inventory optimization techniques. It’s like a treasure hunt, but instead of gold, we’re seeking the perfect balance between minimizing costs and maximizing efficiency.

So, let’s get this party started!

Safety Stock and Reorder Points

Imagine inventory management as a dance between two partners: safety stock and reorder points. Safety stock is your trusty sidekick, always there to prevent stockouts when demand is a bit unpredictable. It’s like a cozy blanket on a cold night, giving you peace of mind.

Reorder points, on the other hand, are the signals that tell you it’s time to replenish your inventory. Think of them as the “low battery” warning on your phone. When you reach the reorder point, it’s time to hit the restock button!

By carefully calculating these two parameters, you can avoid the perils of overstocking (wasting money) and understocking (losing sales). It’s a delicate balancing act, but with the right tools and techniques, you’ll be waltzing through inventory management like a pro.

Inventory Optimization Techniques in Different Industries

Inventory optimization is like a chameleon, adapting to the unique needs of different industries. Let’s take a peek into how it plays out in various fields:

- Retail:Managing a vast array of products with varying demand? No problem! Inventory optimization helps retailers strike the perfect balance between keeping shelves stocked and minimizing excess inventory.

- Manufacturing:Got a complex production process with multiple components? Inventory optimization ensures you have the right parts at the right time, preventing costly delays and keeping production humming along.

- Healthcare:When it comes to medical supplies, having the right inventory on hand is crucial. Inventory optimization helps healthcare providers ensure essential items are always available, saving lives and improving patient outcomes.

Conclusive Thoughts

And there you have it, folks! The art of business inventory has been demystified. By embracing these strategies, you’ll transform your stockpiles into profit-generating machines. Remember, it’s not just about having the right amount of stuff; it’s about maximizing efficiency, minimizing costs, and keeping your customers coming back for more.

So, go forth, conquer your inventory, and become the stockpiling superhero your business deserves!

Commonly Asked Questions

What’s the secret to inventory management success?

A combination of the right tools, techniques, and a healthy dose of common sense!

How can I optimize my inventory levels?

By finding the sweet spot between overstocking and understocking. Safety stock and reorder points are your secret weapons.

What’s the deal with inventory forecasting?

It’s like predicting the future of your inventory, helping you prepare for demand fluctuations and avoid costly surprises.